Recommended Products

- YBX5 Series Flameproof Three-phase Asynchronous Motors

-

Product Category: Explosion-proof motors

Power Range: 0.18 - 375 kW

Frame Size: 80 - 355

Number of Poles: 2, 4, 6, 8

Cooling Method: IC411

Protection Class: IP55

Insulation Class: Class F

Energy Efficiency Class: Grade 1 energy efficiency in GB18613 - 2020 (IE5 according to IEC standards)

- YBX4 Series Flameproof Three-phase Asynchronous Motors

-

Product Category: Explosion-proof motors

Power Range: 0.18 - 375 kW

Frame Sizes: 80 - 355

Number of Poles: 2, 4, 6, 8

Voltage and Frequency: 380V/50Hz

Cooling Method: IC411

Protection Class: IP55

Insulation Class: Class F

Energy Efficiency Class: Grade 2 energy efficiency according to GB18613 - 2020 (IE4 according to IEC standards)

Top articles

YFB3 Series High - Efficiency Dust - Explosion - Proof Three - Phase Asynchronous Motors

Product Information

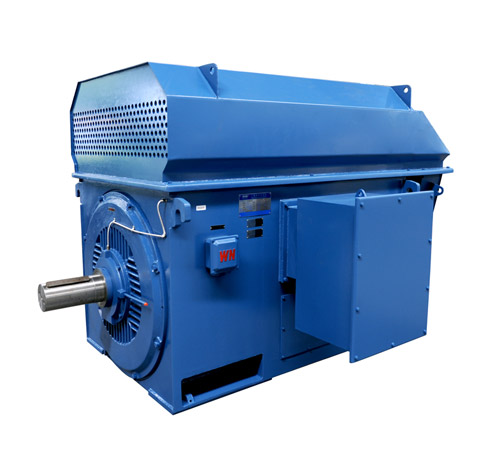

The YFB3 series high - efficiency dust - explosion - proof three - phase asynchronous motors are fully enclosed self - ventilated squirrel - cage three - phase asynchronous motors. This series of motors has the advantages of small size, light weight, reliable operation, beautiful appearance, high efficiency, large temperature rise margin, low vibration, low noise, large starting torque, and advanced explosion - proof structure. The power ratings and installation dimensions comply with the standards of the International Electrotechnical Commission (IEC), and their corresponding relationships are basically the same as those of the German DIN42673 standard, which is beneficial for the matching of exported mechanical equipment and the spare parts of imported equipment.

The motor casings of this series are divided into two types, dust - tight and dust - protected, according to their ability to restrict the entry of dust into the motor casings. The enclosure protection classes are IP6X and IP5X.Product Features

① The casing has high sealing performance to reduce or prevent dust from entering the casing. Even if dust enters, it will not cause an ignition hazard.

② The maximum allowable surface temperature of the casing is controlled not to exceed the specified temperature group, complying with national standards.

③ While ensuring explosion - proof performance, the motor design is optimized to make its efficiency reach the 3rd - level energy - efficiency grade in the national energy - efficiency standard (GB18613 - 2020).

Product Structure

① Stator: The stator core is made of high - quality electrical silicon steel sheets treated by oxidation. The electromagnetic wires and insulation materials use polyester imide enameled wires and high - quality composite insulation. The stator core with windings is impregnated with paint under vacuum and high pressure to form a complete whole, which has excellent electrical, mechanical, moisture - proof and thermal stability. The insulation material uses Class F insulation, but the temperature rise limit is evaluated according to Class B, with a large temperature rise margin and a long service life.

② Rotor: The cast - aluminum rotor is fixed on the shaft by a hot - fitting process. After dynamic balance verification, the motor runs smoothly with low vibration and low noise.

③ Bearings and bearing housings: Special bearings for motors are used. Double - sealed bearings are used for small - frame motors. A wave spring washer is installed in the bearing housing at the shaft extension end face to press against the bearing with moderate elastic force. The bearing structure at the non - shaft extension end can prevent axial movement, reducing vibration and noise during the motor's operation. Open - type bearings are used for large - frame motors, and there are oil injection and drainage devices at the bearing parts, enabling the addition of grease without stopping the machine.

④ Fan and fan cover: The fans of the whole series are key - connected to the shaft for reliable operation. The fan cover is made of thin steel plate. On the premise of preventing foreign objects of a certain size from entering, the maximum ventilation area is obtained, ensuring smooth air flow and a beautiful appearance.

Operating Conditions

① The ambient air temperature varies with the seasons, but does not exceed 40°C, and the minimum ambient air temperature is - 15°C.

② The altitude does not exceed 1000m.

③ The average maximum relative humidity in the wettest month is 90%, and the average minimum temperature in the same month is not higher than 25°C.

④ The rating is a continuous rating based on continuous duty (S1).

⑤ The rated frequency of the motor is 50Hz, and the rated voltage is 380V.